Product Overview

Product Overview

✔ A famous and leading manufactory for sheet metal fabrications machines

✔ With 20 years industry-area experiences specially in shearing machine,press brake,rolling ,lathe,milling,laser and plasma

cutting machines

✔ A mass of far-flung agents and partners globally

✔ CE ,UKCA ,Saudi Arabia,Russia certification and also Edwards Pearson European quality standard.

✔ 70 Years history brand Edwards Pearson European Brand

✔ The best timely and responsible service company in machinery area

✔ A team of professional technician team in China and oversea

✔ Reliable technicial guidance

✔ High technology self-design and structure update with innovation

✔ Customer-oriented design ,OEM and service

✔ Dramatical achievement cooperation and collaboration

EDWARDS PEARSON SHEARING MACHINE

✔ Hydraulic material plate clamping ensure accurate shearing

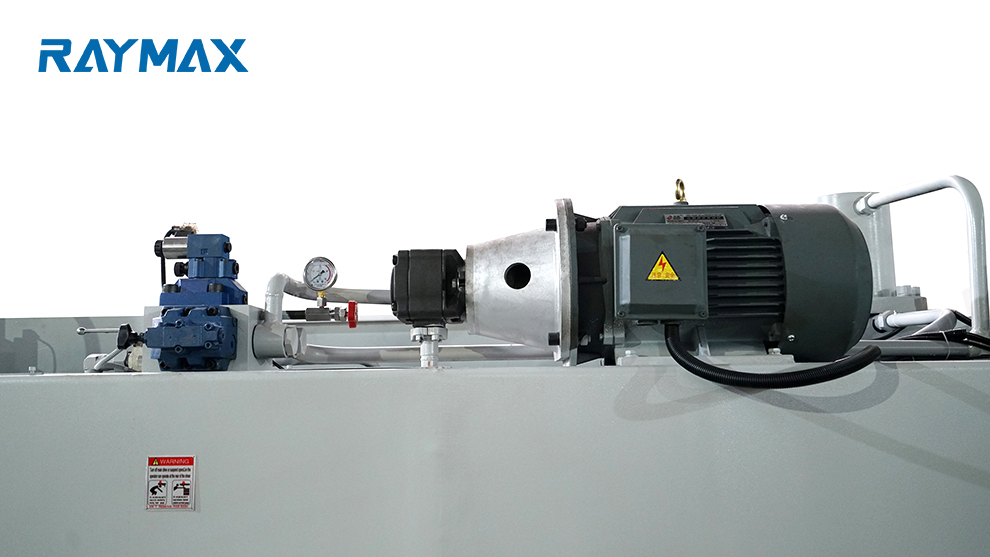

✔ Hydraulic operated machine

✔ Squaring arm incorporating flip over stops

✔ Motorised backgauge ,NC GO TO Controller E21 SYSTE

✔ Roving foot pedal control

✔ Individual hydraulic clamping system with Nylon Pads to protect material from Indentation

✔ Blades made from 6CrW2Si material suitable for cutting stainless steel

✔ Plate support tables with transfer balls for quick & easy material alignment and manoeuvrability

✔ Rear guarding with 3 SETS of photo Electric sensors

✔ Heavy duty swing beam machine structure

✔ Equipped with shadow line lighting-aligment device

✔ Stroke counter an short stroke adjustment

Spesifikasjon

Spesifikasjon | Shear Thickness | Shear Width | Shearing Angle | Number of Stroke | Backgauge Rang | Motor Power |

mm | mm | (° ) | min-1 | mm | kw | |

QC12Y-4×2500 | 4 | 2500 | 1° 30 | 20 | 20~600 | 4 |

QC12Y-4×4000 | 4 | 4000 | 1° 30 | 18 | 20~600 | 5.5 |

QC12Y-6×3200 | 6 | 3200 | 1° 30 | 14 | 20~600 | 7.5 |

QC12Y-6×5000 | 6 | 5000 | 1° 30 | 10 | 20~800 | 11 |

QC12Y-8×2500 | 8 | 2500 | 1° 30 | 14 | 20~600 | 7.5 |

QC12Y-8×4000 | 8 | 4000 | 1° 30 | 8 | 20~600 | 7.5 |

QC12Y-8×6000 | 8 | 6000 | 1° 30 | 6 | 20~800 | 15 |

Product Overview

Product Overview