Hovedtrekket

● The whole machine is in sheet plate welded structure, entire welded frame, with internal stress eliminated by vibration aging technology, high strength and good rigidity of hydraulic press brake machine.

● Dobbel hydraulisk oljesylinder brukes for øvre transmisjon, utstyrt med mekanisk endestopper og synkron torsjonsstang, typisk for stabil og pålitelig drift, samt høy presisjon.

● Electrical control and manual fine-tuning mode are adopted for distance of rear stopper and stroke of gliding block, and fitted with digital display device, easy and quick in use.

● Slider stroke adjusting device and back gauge device: electric quick adjusting, manual micro adjusting, digital display, easy and quick in use.

● Med en 180-graders svingbar bom er den enkel å bruke og feilsøke, og er installert for å passe høyden på menneskekroppen.

● Using CT12 CNC system, touch screen operation, direct and efficient.

● Med vinkelprogrammeringsfunksjon kan nullbasert opplevelse også betjenes.

● Equipped with a quick clamping of the mold to quickly change the mold.

● Electro-hydraulic synchronous proportional valve control accuracy, bending accuracy is higher.

● Double-axis rear material structure, high-strength channel steel material, strong high-precision zero clearance.

● Adopt the domestic first-class brand of oil cylinders, and use imported German hydraulic valve sets, the quality is guaranteed.

● Upper workbench have Straight line adjusting mechanism to eliminate long-term use of mechanical error.

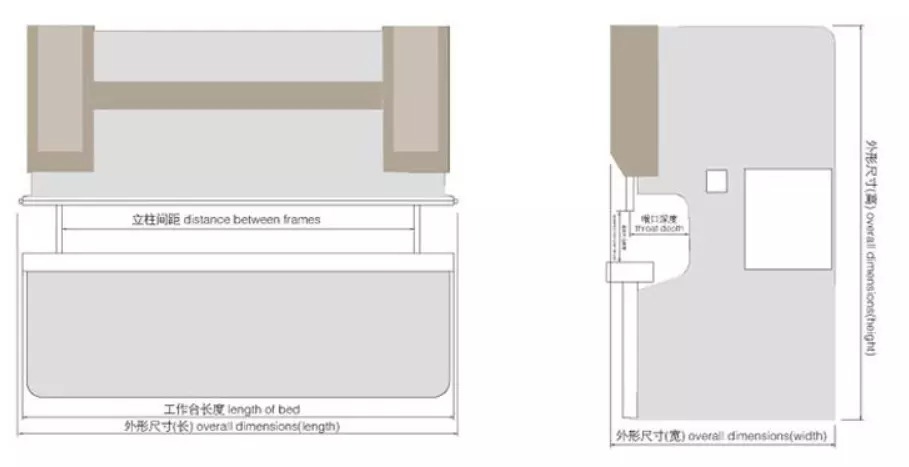

Large size throat can be process larger workpiece.

Standard utstyr

Sikkerhetsstandarder (2006/42/EC):

1. EN 12622:2009 + A1:2013

2. EN ISO 12100:2010

3. EN 60204-1:2006+A1:2009

4. Frontfingerbeskyttelse (sikkerhetslysgardin)

5. Sør-Korea Kacon fotbryter (sikkerhetsnivå 4)

6. Sikkert gjerde på baksiden med CE-standard

CybTouch CNC-kontroller

CybTouch CNC-kontroller fra Sveits

●12" color LCD display, LCD Touch screen, icon recognition function

●The “EasyBend” page is processed with easy single bending

●The fully efficient bending programming can meet the needs of mass production and processing.

●Automatically calculate bending angle, main pressure and deflection compensation.

●Automatic calculation of bending data.

●Automatic calculation of pressure and deflection compensation.

●Automatic calculation of upper die depth.

●Angle, rear gear correction 2D graphics programming.

●Automatically simulate the bending sequence and provide the best bending scheme (option)

The feature:

Enkel betjening

Stor, levende berøringsskjerm med høy kontrast.

Enkle sider, tydelig display, store taster.

Intuitivt brukervennlig grensesnitt.

Komplett programmering for effektiv masseproduksjon med flere bend.

Enkel enkeltbøy med Easy Bend-side.

Online hjelp og interaktive advarsler.

Komfortabel trådløs sikkerhetskopiering av data og programvareoppdatering ved hjelp av PC eller bærbar PC.

Large variety of languages available.

Bedre bøying

Ulike automatiske beregninger av bøyefunksjoner.

Bøyesekvenser og programmer kan lagres.

Vinkel-, trykk- og kronestyring.

Enkel manuell bevegelse.

Offline 2D software available.

Kraftig

Styrer 4+1 akser

Automatic bend sequencing (option).

Beregning av bøyningsgodtgjørelse.

Pressure - crowning calculation.

Modulære verktøy for hver del eller bend.

Korreksjon av vinkel og bakmål.

Tele maintenance via wireless connection with PC or notebook.

USB-port for minnepinne for dataoverføring/sikkerhetskopiering.

CybTouchTools

All CybTouch come with CybTouchTools, which allows to wirelessly transferring data between a PC and CybTouch (requires optional RFLink USB key). It is used to backup/restore machine parameters, tools and parts, as well as updating the firmware.

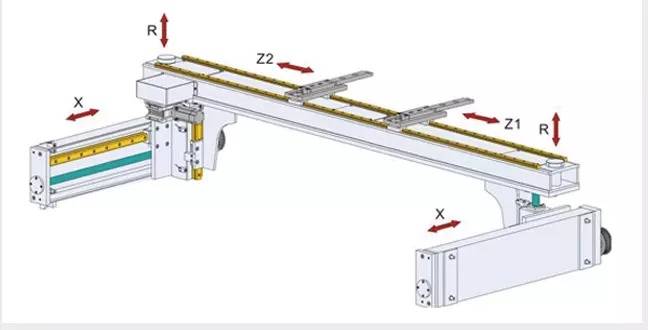

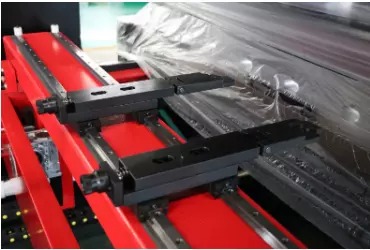

CNC back gauge 4+1 axis

Adjustment of back gauge is controlled by servo motor

Synchronous belt transmission system, combined with high-precision guide rail screw to improve work efficiency, work repeat accuracy ± 0.015mm

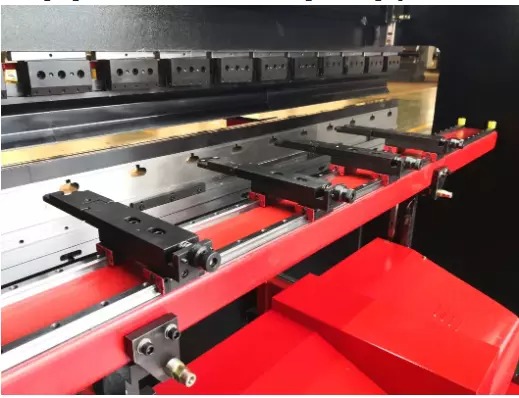

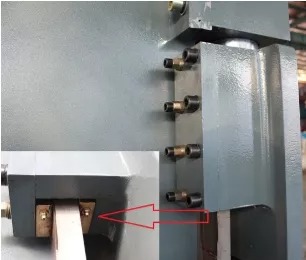

Hurtigklemme

1. Formen kan installeres og fjernes til venstre og høyre når du trekker i det røde håndtaket

2. Formen kan installeres opp og ned når du trykker på knappen

3. Scale more accuracy

Schneider Electrical system

Equipped with dust proof cabinet to guarantee the high quality electrical system. It conforms to international standards, is safe and reliable, has a long service life, and has strong anti-interference ability. The electrical cabinet is equipped with a Cooling device.

Open door power off

Electric cabinet with function of opening door to cut off power.

The stopper

The stopper move left and right on two linear guides.

High precision

High precision electric table crowning

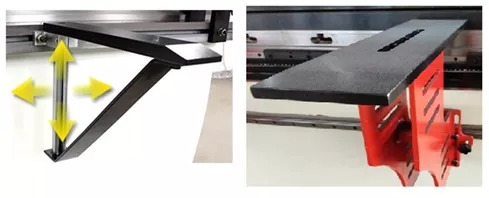

Dobbel struktur foran arm

Double structure front arm is higher rigidity, superior carrying capacity .It can be adjusted up and down or move along the workbench from side to side

It can reduce labor intensity and improve productivity.

Quick clamp

1. Formen kan installeres og fjernes til venstre og høyre når du trekker i det røde håndtaket

2. Formen kan installeres opp og ned når du trykker på knappen

3. skala mer nøyaktighet

The guideway use the brass, wear-resistance, long service life

Novel and unique dual linear guide rail structure to ensure excellent positioning accuracy

High-precision grating scale mounted on C-board.

Pedal switch with emergency stop.

Servo Motor and drive satisfy high precision positioning requirements.

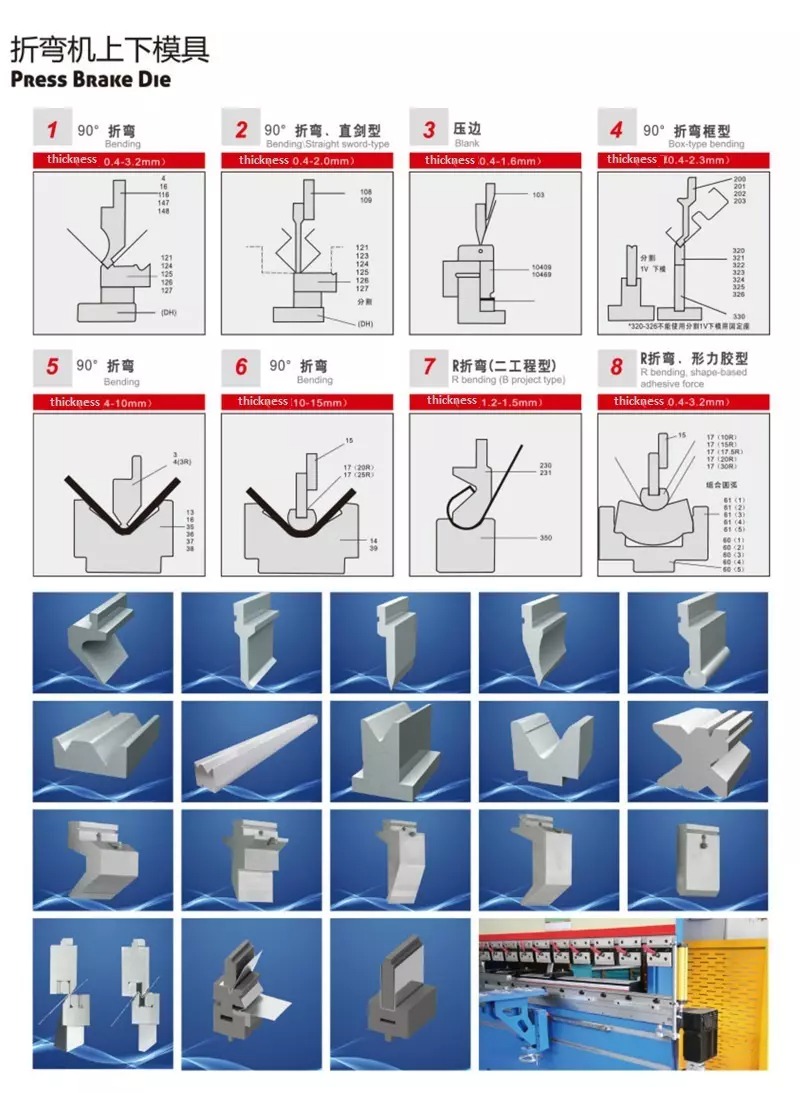

All machines and molds (die/punch) can be customized according to requirements

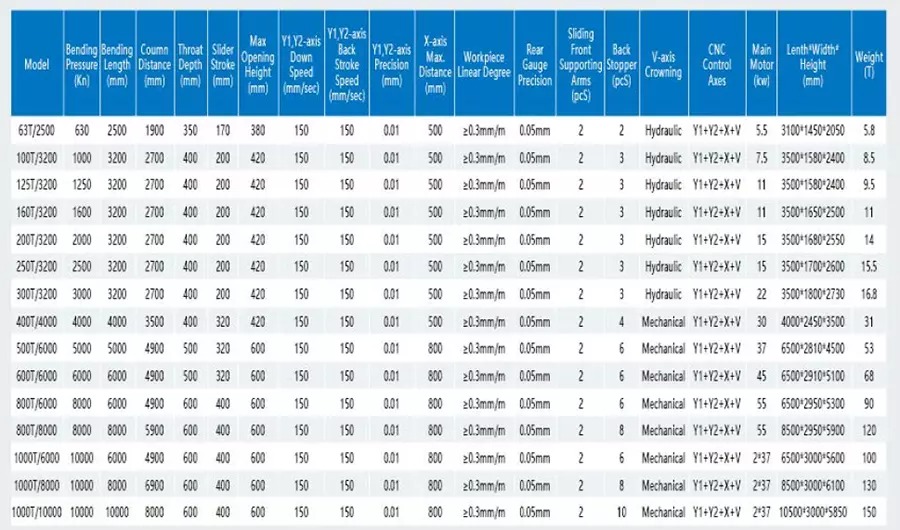

Teknisk