| guillotine shearing machine | swing beam shearing machine | |

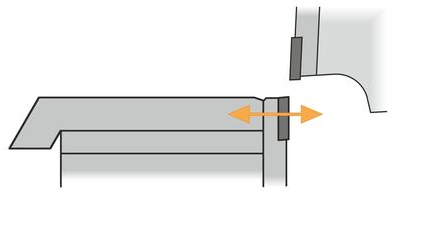

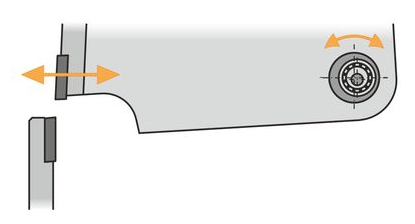

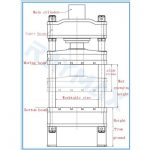

| Beam move direction | the upper beam moves straight | the swing beam moves with the upper blade in a circular arc |

| Blade holder | The blade holder of the guillotine shearing machine moves vertically and linearly with respect to the lower blade edge to ensure that the shearing sheet is twisted and deformed with small straightness and more accurate. | The blade holder body of the swing beam shearing machine is curved, and it uses arc point contact to ensure the straightness of the sheared material. |

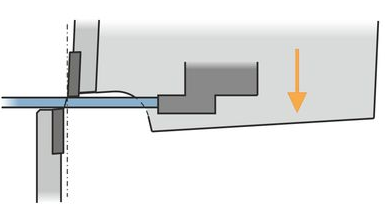

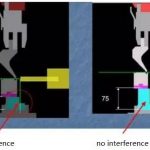

| Upper blade penetration | Upper blade penetrates the material with an offset (blade clearance) to the lower blade. ● Oblique fractured cutting line. ● Bigger burr especially when the blades are not sharp.

| The upper blade penetrates the metal sheet above the lower blade. ● Clean, right-angled cuts with almost no burr.

|

| Upper and lower blade | ● The upper and lower blade rub on each other when the blade clearance is low, so blades go dull. ● Frequent blade changes required.

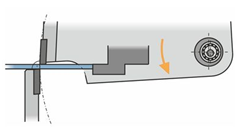

| ● The cut is made by a pivoting movement of the swing beam. After the cut is made the upper blade moves away from the lower blade. Prevents the blank from jamming between the lower blade and the backstop. ● No need frequently change the blade.

|

| Blade clearance adjustment | ● Tedious and costly clearance adjustment by repositioning the shear table. ● Long downtimes. ● Often compromises in the cutting quality.

| ● The blade clearance can be easily adjusted by simply turning the cutting gap eccentric. ● Short setup times. ● Automatic adjustment on higher capacity machines.

|

| Sectional view of the blade | Square | Diamond-shaped quadrilateral shape |

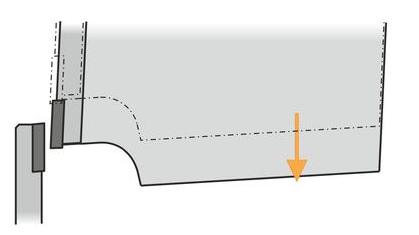

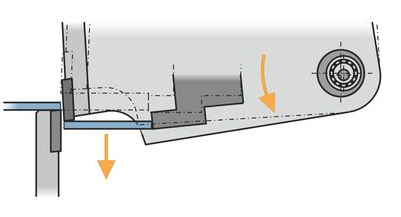

| Motion track of the blade | The blade moves vertically | The blade moves with a slight arc when cutting the plate. |

| Planes of the blade interchange | The four planes of the blade can be exchanged. | The two planes of the blade can be used interchangeably. |

| Stability | When the machine is running, the oil cylinders at both ends drive the upper blade to move up and down linearly, with strong stability. | When the machine is running, the oil cylinders at both ends drive the upper blade to move up and down in an arc. Therefore, the stability is not as good as the guillotine shears. |

| Thickness of cutting boards | The hydraulic guillotine shearing machine is suitable for cutting boards over 10mm. | Swing beam shearing machine s are suitable for cutting thin plates below 10mm (including 10mm). |

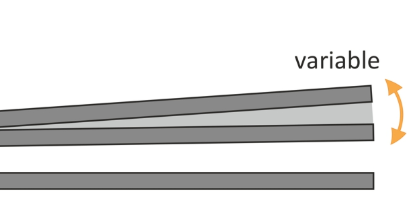

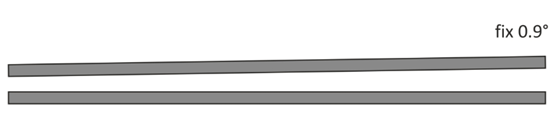

| The shear angle | The shear angle of the guillotine shearing machine can be adjusted. | The shear angle of the swing beam shearing machine is fixed and cannot be adjusted. |

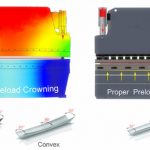

| Cuts | Twist cuts The hydraulic guillotine shearing machines use a variable rake angle. Low rake angle for thin materials. High rake angles for thicker materials. Machines can be built lighter. The results are twisted parts with narrow strips.

| Twist-free cuts Swing beam cutting requires a riding shear design. The reason is the low rake angle, which is the fix for any material thickness. Low rake angle results in twist-free parts starting at about 10-15 x sheet thickness.

|