Hydraulic Press Machine is often used in pressing and pressing forming processes, such as forging press, stamping, cold extrusion, straightening, bending, flanging, sheet drawing, powder metallurgy, pressing, etc. As a professional hydraulic press machine manufacturer and hydraulic press company, RAYMAX has a variety of hydraulic press machine for sale designed to support sheet metal machining requirements. These are compact in size and ideal to work with metal sheets of different metals.

Hydraulic Power Press Machine hjelper med å konvertere metallplater til forskjellige former med færre muligheter for sløsing eller skader på metallplater. Det er også et bedre alternativ for å bøye eller forme metallplater enn konvensjonell eller manuell formingsprosess. Det er mange funksjoner som gjør at vår industrielle hydrauliske presse forblir allsidig blant det kompakte utvalget av plateutstyr.

Fordeler med hydraulisk kraftpressemaskin

● Et bredt spekter av design

Det finnes mange forskjellige typer hydrauliske kraftpressemaskiner som er egnet for forskjellige bruksområder. Noen av de forskjellige typene presser er; Vertikal H-ramme-stil, C-rammepresser, Horisontalpresser, Bevegelige bordpresser, Dekkpresser, Bevegelige rammepresser og Lab-presser. Hvert design er også tilgjengelig med enkelt- eller dobbeltvirkende arbeidshoder, og manuell, luft- eller elektrisk betjening.

● Glatt pressing

Hydraulikk gir deg jevnt, jevnt trykk gjennom hele ramslaget. Dette gjør at tonnasje kan oppnås på et hvilket som helst punkt av stemplet, i motsetning til mekaniske presser hvor du bare får tonnasjen i bunnen av slaget.

● Trykkkontroll

Mange hydrauliske pressemaskiner til salgs har trykkavlastningsventiler tilgjengelig. Du kan slå inn det trykket du trenger, og pressen vil gjenta det forhåndsinnstilte trykket konsekvent og ta gjettingen ut av ligningen for mye eller for lite trykk.

● Evne til å løfte og trykke

Mange hydrauliske pressemaskiner til salgs har dobbeltvirkende sylindre som betyr at du har løftekraft så vel som pressekrefter. Eventuelle verktøy festet til stempelet kan enkelt heves med den dobbeltvirkende sylinderen.

● Reduser vekt og spar materialer

Hydroforming is an advanced manufacturing technology for realizing a lightweight structure. Compared with the traditional stamping process, the hydroforming process has obvious advantages over reducing the weight of products. For typical parts such as automobile engine bracket and radiator bracket, hydraulic forming parts are 20% - 40% lighter than stamping parts. For hollow step shaft parts, the weight can be reduced by 40% - 50%. In the automotive industry, aviation, aerospace fields, it is a long-term goal to reduce the structural quality and save energy in operation.

As a professional hydraulic press machine manufacturer and hydraulic press company, RAYMAX's hydraulic presses are ideal for assembly, straightening, fabrication, quality control, maintenance, product testing, bending, forming, punching and shearing. Every hydraulic power press has a frame that is constructed of heavy-duty arc-welded steel and seamless steel cylinders to prevent leaks.

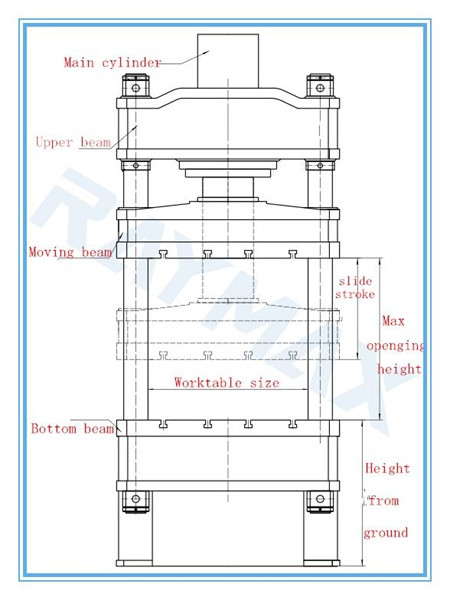

Hovedtrekket

● This series of hydraulic press machine for all stretching, bending, forming, blanking, flanging and other processes.

● With computer optimization of structural design, four-post structure(simple, economical, practical) and solid frame structure, 3-beam 4-column. It is good rigidity ,high precision and anti-bias ability

● The hydraulic control adopts plug-in integrated system ,reliable operation, long service life, less hydraulic impact, lead to less connection piping and leakage point.

● PLC control electrical system ,compact structure, works sensitively reliably ,flexibly

● Through the operation panels selection, not only can achieve constant stroke, constant pressure 2 molding process, but also to achieve. with pad, no pad, ejection there process working cycle

● The Slider could be adjustable :slide operating pressure, fast down idle stroke, slow pressing strok

● Cartridge valve equipped for hydraulic control system ,reliable ,durable and less hydraulic shock ,shorter connection pipeline and fewer release points, hydraulic integrated system is adopted separate control unit.

Hydraulic press

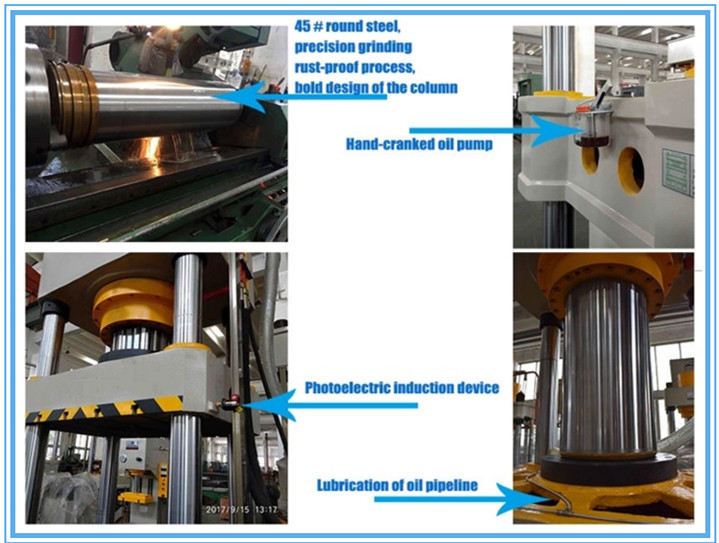

Machined:

Machine frame will be putted into the tempering furnace to remove the internal stress after welded, hydraulic power press machine lifetime will be much longer.

Modern five-sided machining center and CNC boring and milling machines perform machining to ensure the highest precision of the workpiece .

Cylinder:

The master cylinder is designed for high speed, small motor power, fast lifting speed and high efficiency.

The piston rod is made by heat treatment, using high quality imported seal, high wear resistance and durability. High guidance accuracy .

Hydraulic and electric:

All pipelines and flanges have been subjected to vibration and oil leakage tests , which greatly reduce oil leakage from pipelines, and are easy to maintain and safe.

The hydraulic system is equipped with overload overflow protection to ensure no leakage and level gauge for direct reading and checking of the oil level.

Variable pump provides high pressure, high speed, durability and low noise.

The suction port of the oil pump is equipped with an oil filter to ensure the cleanliness of the pump and hydraulic system.

All electrical, hydraulic and mechanical components are in line with industry standards and products are spread throughout North America and Europe.

Safety:

In order to prevent the slider from falling down, the machine is provided with hydraulic support safety circuit.

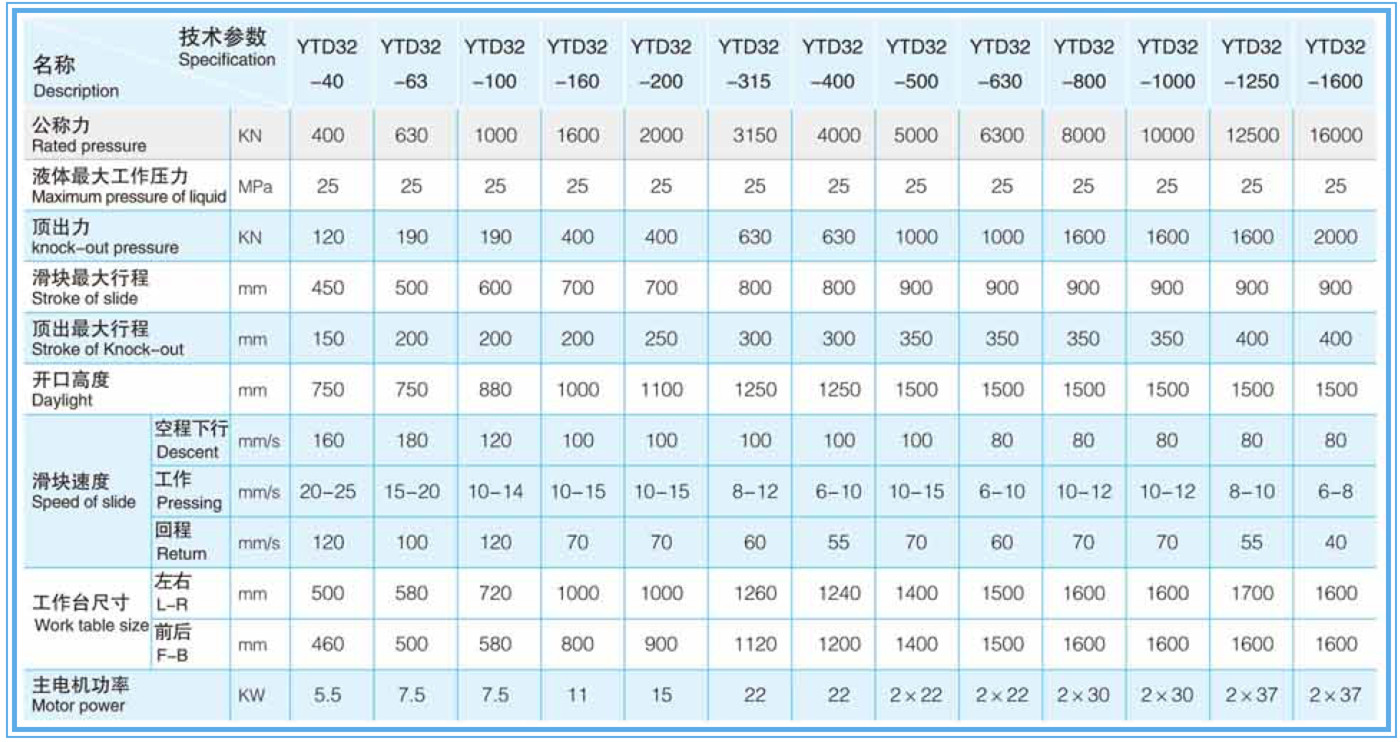

Teknisk

Product