JH21 Hydraulic Punching Machine can be used to cut holes of any shapes in materials. There are multiple types of Sheet Punching Machines used to cut holes on metal sheets such as MS/SS/Aluminium/Copper/Brass etc. The hydraulic punch press can also punch Angle, I-beam, Plates and C Channel. Punching Shapes can include oblong hole punching, slot hole punching, round hole punching, and square hole punching and many others as required.

Fordeler med hydraulisk stansemaskin

● Høy stivhet

● Stabil høy presisjon

● Pålitelig og sikker drift

● Automatisert produksjon, arbeidsbesparende, høy effektivitet

● Glidejusteringsmekanisme

● Ny design, miljøvern

● Bedre formings- og tegneevner

● Bedre for mindre løp.

● Variasjoner i stengehøyde påvirker ikke kraften som kan påføres

Bruk av hydraulisk stansemaskin

Platestansemaskinen for salg er mye brukt i stempling og forming av elektronikk, kommunikasjon, datamaskiner, husholdningsapparater, møbler, transport (biler, motorsykler, sykler), metalldeler, etc.

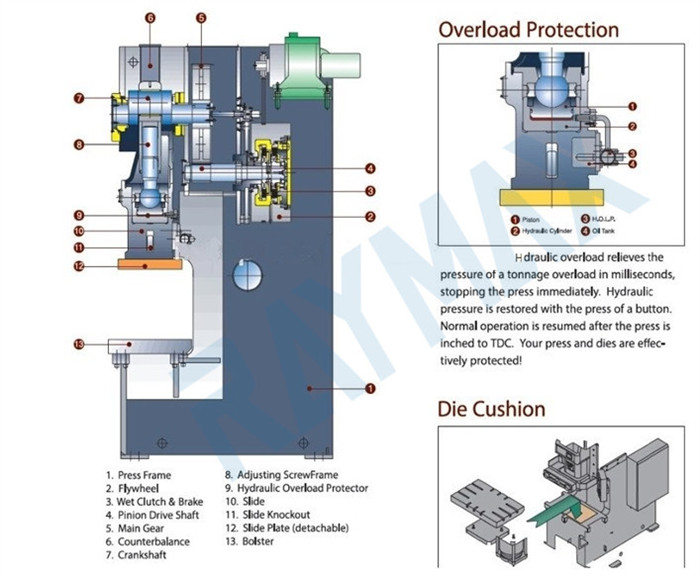

Whole structure of the Power Press

1. Steel plate welded c frame body, heat treatment, produced by cnc boring and milling center, high rigidity, accuracy and stability;

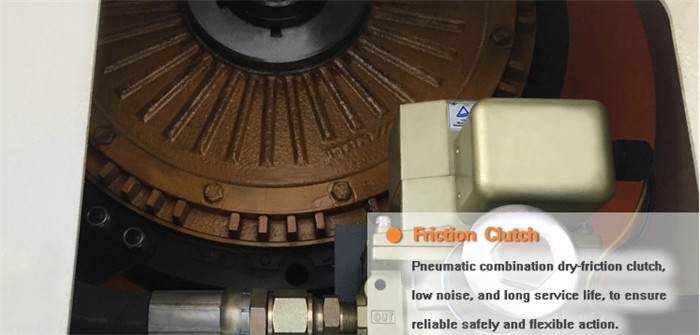

2. Wet type pneumatic clutch with safety solenoid valve, lower noise and longer service life.

3. Best quality gears, bushes, cylinders, link rods and ball screw ensure the high performance, high reliability and longer service life.

4. Hydraulic overload protected system is standard equipped. The press will stop with oil pressure release if overload to protect the press and the die. It is easy to reset to normal status.

5. The hydraulic punching machine for sale adopts pneumatic balancing device design method greatly ensures the relative stability of the machine operation. Molding accuracy up to 0.1mm, safe, portable, reliable.

6. Adopts combined pneumatic friction clutch and brake.

7 . Cluster gear adopts the flooding oil lubrication.

8 . Equipped with hydraulic overload protecting device.

9 . Six-face rectangular lengthened guide, CP1-315B/400B with eight–face lengthened guide

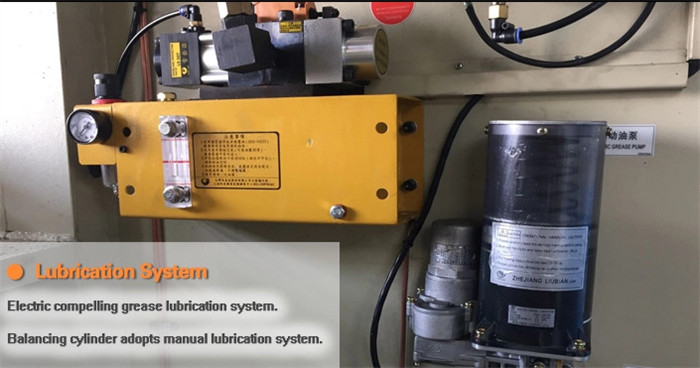

10. Electric compelling grease lubrication system.

11. Balancing cylinders adopts manual lubrication system.

12. One set of blowing device.

Teknisk

| JH21-25B | JH21-25 | JH21--45 | JH21-63 | JH21-80 | JH21-110 | JH21-125 | JH21-160B | |||

| Capacity | kN | 250 | 250 | 450 | 630 | 800 | 1100 | 1250 | 1600 | |

| Nominal Stroke | mm | 3 | 3 | 4 | 4 | 5 | 6 | 6 | 6 | |

| Slide Stroke | mm | 60 | 80 | 100 | 120 | 140 | 160 | 160 | 160 | |

| SPM | Fixed | min-1 | 100 | 100 | 80 | 70 | 60 | 50 | 50 | 40 |

| Variable | 80-120 | 80-120 | 70-90 | 60-80 | 50-70 | 40-60 | 40-60 | 35-50 | ||

| Max. Die Height | mm | 200 | 250 | 270 | 300 | 320 | 350 | 350 | 350 | |

| Die Height Adjustment | mm | 50 | 50 | 60 | 80 | 80 | 80 | 80 | 110 | |

| Between Slide Center & Frame | mm | 160 | 210 | 230 | 300 | 300 | 350 | 350 | 380 | |

| Bolster (FB×LR) | mm | 300×680 | 400×700 | 440×810 | 580×900 | 580×1000 | 680×1150 | 680×1150 | 740×1300 | |

| Bolster Opening (Up Hole Dia.×Dpth×Low Hole Dia.) | mm | 130×260 | φ170×20 ×φ150 | φ180×30 ×φ160 | φ200×40 ×φ180 | φ200×40 ×φ180 | φ260×50 ×φ220 | φ260×50 ×φ220 | φ300×50 ×φ260 | |

| Bolster Thickness | mm | 70 | 80 | 110 | 110 | 120 | 140 | 140 | 150 | |

| Bolster Opening (Dia./FB×LR) | mm | 200×270 | 260×250 | 300×300 | 390×460 | 390×520 | 420×540 | 420×540 | φ470 | |

| Slide Area (FB×LR) | mm | 270×330 | 300×360 | 340×410 | 400×480 | 420×560 | 500×650 | 540×680 | 580×770 | |

| Shank Hole (Dia.×Dpth) | mm | φ40×60 | φ40×60 | φ40×60 | φ50×80 | φ50×80 | φ60×80 | φ60×80 | φ65×85 | |

| Between Columns | mm | 448 | 450 | 550 | 560 | 640 | 760 | 760 | 850 | |

| Main Motor Power | kW | 3 | 3 | 5.5 | 5.5 | 7.5 | 11 | 11 | 15 | |

| Outline Size (FB×LR×H) | mm | 1150×1050 ×2050 | 1300×1050 ×2050 | 1390×1200 ×2400 | 1580×1210 ×2520 | 1640×1280 ×2700 | 1850×1450 ×3060 | 1850×1490 ×3060 | 2280×1550 ×3240 | |

| Net Weight | kg | 2200 | 2600 | 3450 | 5400 | 7000 | 9340 | 9900 | 14500 | |

Controller System and Cluth

● The Press adopts the low inertia combined dry pneumatic friction clutch and brake , Smoother press performance, easier maintenance, to ensure reliable safety and flexible action Low noise, long service life.

● Driving gear is installed into the frame and gear is immersed in oil reservoir. Customer could choose Electromagnetic governor.

● Use adopts dual valve which can guarantee the safety and reliability of clutch.

● Pneumatic dual balance cylinder, which balances the slide block and punch weight to reduce noise and impact;

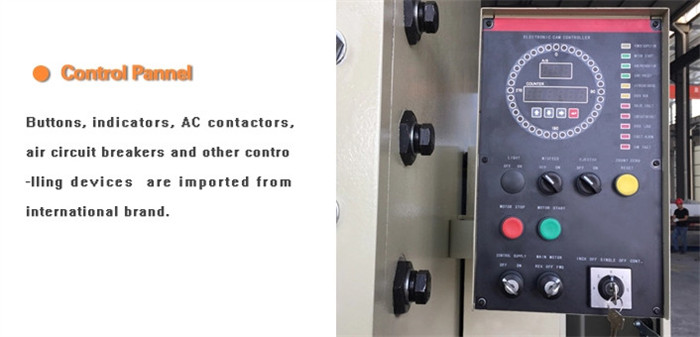

● The press adopts cam controller which be combined with proximity switch (Schneider)

Detail