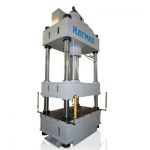

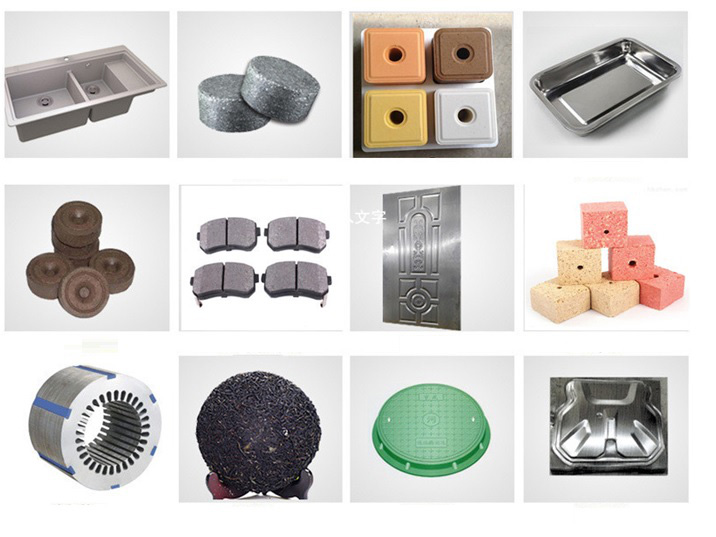

Hydraulic press machine, also known as hydraulic power press machine, is a machine that uses hydrostatic pressure to process metal, plastic, rubber, wood, powder and other products. It is commonly used in the pressing process and the forming process, such as: forging, stamping, cold extrusion, straightening, bending, flanging, sheet drawing, powder metallurgy, pressing, etc. The hydraulic press machine for sale is generally composed of three parts: a host, a power system and a hydraulic control system. The hydraulic presses are classified into valve hydraulic presses, liquid hydraulic presses, and engineering hydraulic presses.

Working principle

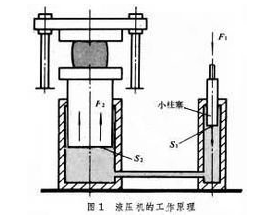

The working principle of hydraulic press machine. The areas of the large and small plungers are S2 and S1, and the acting force on the plunger is F2 and F1, respectively. According to the Pascal principle, the pressure of the sealed liquid is equal everywhere, that is, F2/S2=F1/S1=p; F2=F1(S2/S1). This represents the gain effect of hydraulic pressure. Like mechanical gain, the force increases, but the work does not gain. Therefore, the moving distance of the large plunger is S1/S2 times the moving distance of the small plunger.

The basic principle is that the oil pump delivers hydraulic oil to the integrated plug-in valve block, and distributes the hydraulic oil to the upper or lower chamber of the cylinder through various check valves and overflow valves. Under the action of high-pressure oil, the cylinder moves. A industrial hydraulic press machine is a device that uses liquid to transmit pressure. The liquid follows the Pascal's law when transmitting pressure in a closed container.

Drive system

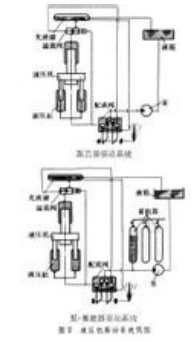

The driving system of the hydraulic machine mainly has two types of pump direct drive and pump-accumulator drive.

Pump direct drive

The pump of this drive system provides high-pressure working fluid to the hydraulic cylinder, the distribution valve is used to change the direction of liquid supply, and the overflow valve is used to adjust the limited pressure of the system and at the same time play a safety overflow role. This driving system has few links and a simple structure, and the pressure can be automatically increased or decreased according to the required working force, which reduces the power consumption. But the capacity of the pump and its driving motor must be determined by the maximum working force and the maximum working speed of the hydraulic press. This type of drive system is mostly used in small and medium-sized hydraulic presses, and it is also a large (such as 120,000 kN) free forging hydraulic press directly driven by a pump.

Pump-accumulator drive

There is one or a group of accumulators in this drive system. When there is a surplus of high-pressure working fluid supplied by the pump, it is stored by the accumulator; and when the supply quantity is not enough, it is replenished by the accumulator. Using this system, the capacity of the pump and motor can be selected according to the average amount of high-pressure working fluid, but because the pressure of the working fluid is constant, the power consumption is large, and the system has many links and the structure is relatively complicated. This type of drive system is mostly used for large hydraulic machines, or a set of drive systems to drive several hydraulic machines.

Structure type

According to the direction of the force, there are two types of hydraulic presses: vertical and horizontal. Most hydraulic presses are vertical, and hydraulic presses for extrusion are mostly horizontal. According to the structure type, the hydraulic press machine has double-column, four-column, eight-column, welded frame and multi-layer steel belt winding frame and other types. Medium and small vertical hydraulic machines also use C-frame type. C-frame hydraulic press is open on three sides, easy to operate, but poor in rigidity. The welded frame hydraulic press for stamping has good rigidity and is open at the front and rear, but closed at the left and right.

In the vertical four-column free-forging hydraulic press machine for sale with upper drive, the cylinder is fixed in the upper beam, the plunger is rigidly connected with the movable beam, and the movable beam is guided by the vertical column and moves up and down under the pressure of the working fluid. There is a worktable that can move back and forth on the beam. Install an anvil and a lower anvil under the movable beam and on the worktable respectively. The working force is borne by the frame composed of upper and lower beams and columns. Large and medium-sized free-forging hydraulic presses driven by pump-accumulators often use three working cylinders to obtain a three-stage working force. Outside the working cylinder, there is a balance cylinder and a return cylinder which apply upward force.

Hydraulic press machine, also known as hydraulic power press machine, is a machine that uses hydrostatic pressure to process metal, plastic, rubber, wood, powder and other products. It is commonly used in the pressing process and the forming process, such as: forging, stamping, cold extrusion, straightening, bending, flanging, sheet drawing, powder metallurgy, pressing, etc.

Classification of hydraulic press machine

According to the structure form, it is mainly divided into four-column type, single-column type (C type), horizontal type, vertical frame, universal hydraulic machine, etc.

According to usage, it is mainly divided into metal forming, bending, stretching, punching, powder (metal, non-metal) forming, pressing, and extrusion.

1. Hot forging hydraulic press machine

The large forging hydraulic press machine for sale is forging equipment that can complete various free forging processes and is one of the most widely used equipment in the forging industry. At present, there are forging industrial hydraulic presses of 800T, 1600T, 2000T, 2500T, 3150T, 4000T, 5000T, and other specifications.

2. Four-column hydraulic press machine

The hydraulic power press machine is suitable for the pressing process of plastic materials, such as powder product molding, plastic product molding, cold (hot) extrusion metal molding, sheet stretching, as well as transverse pressure, bending pressure, turning, correction and other processes. The four-column hydraulic press machine for sale can be divided into a four-column two-beam hydraulic press, four-post three-beam hydraulic press, four-post four-beam hydraulic press, etc.

3. Single column hydraulic press machine

The single-column hydraulic press machine is also called a single-arm hydraulic power press machine. It can expand the working range, use three sides of the space, lengthen the stroke of the hydraulic cylinder (optional), the maximum expansion and contraction 260mm-800mm. Moreover, the hydraulic press machine for sale has a hydraulic system cooling device and can preset the working pressure.

4. Double column hydraulic press machine

This series of products are suitable for the pressing and fitting of various parts, bending and shaping, embossing and indentation, flanging, punching, and shallow drawing of small parts and the molding process of metal powder products. Double column hydraulic press machine adopts electric control, with a jog and semi-automatic circulation, can keep pressure delay and has good slider guidance, easy operation, easy maintenance, economic and durable. According to the user's needs, the hydraulic power press machine can add additional functions such as thermal instruments, ejector cylinders, stroke digital display, and counting.

5. Gantry hydraulic press machine

The machine parts can be assembled, disassembled, straightened, calendered, stretched, bent, punched, etc. by hydraulic press machine, truly achieving one machine with multiple uses. The working table of the hydraulic press machine for sale can move up and down, the size expands the opening and closing height of the machine, and the use is more convenient.

Advantage of hydraulic press machine

For hollow variable cross-section structural parts, the traditional manufacturing process is to stamp and form two halves, and then weld them into a whole. However, the hydroforming can form a hollow structural part with a change in cross-section along the component in one piece. Compared with the stamping and welding process, the hydroforming technology and process have the following main advantages:

1. Reduce quality and save materials.

For typical parts such as automobile engine brackets and radiator brackets, the weight of hydroformed parts can be reduced by 20% to 40% compared to stamping parts. For hollow stepped shaft parts, the weight can be reduced by 40% to 50%.

2. Reduce the number of parts and molds, reduce mold costs.

Hydroformed parts usually only need one set of molds, while stamping parts usually require multiple sets of molds. The number of hydroformed engine bracket parts was reduced from 6 to 1, and the number of radiator bracket parts was reduced from 17 to 10.

3. Reduce the amount of welding for subsequent mechanical processing and assembly.

Taking the radiator bracket as an example, the heat dissipation area is increased by 43%, the number of solder joints is reduced from 174 to 20, the process is reduced from 13 to 6, and the productivity is increased by 66%.

4. Improve strength and stiffness

It can improve strength and stiffness, especially fatigue strength, such as a hydroformed radiator bracket. Its stiffness can be increased by 39% in the vertical direction and 50% in the horizontal direction.

5. Reduce production costs.

According to the statistical analysis of the hydroforming parts that have been applied, the production cost of hydroforming parts is reduced by an average of 15% to 20% compared with stamping parts, and the mold cost is reduced by 20% to 30%.

Application of hydraulic press machine

The hydraulic press machine has a wide range of applications in the automotive, aerospace, aerospace, and pipeline industries. It is mainly applicable to round, rectangular, or shaped cross-section hollow structural parts that vary along the axis of the component, such as automobile exhaust system shaped pipes; non-circular cross-section Hollow frames, such as engine brackets, instrument panel brackets, and body frames (approximately 11% to 15% of the mass of the car); hollow shaft parts and complex pipe parts, etc.

Suitable materials for hydraulic power press machines include carbon steel, stainless steel, aluminum alloy, copper alloy, and nickel alloy, etc. In principle, materials suitable for cold forming are all suitable for hydraulic press machine. The hydraulic press machine for sale is mainly aimed at auto parts factory, electronics factory, electrical appliance factory, heat treatment factory, vehicle parts factory, gear factory, air conditioning parts factory.