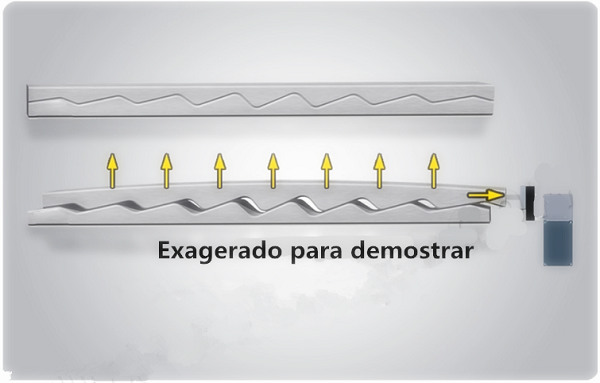

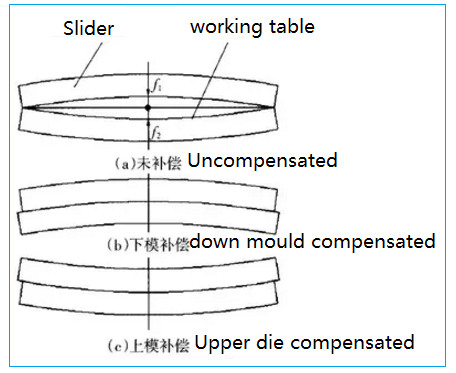

The CNC bending machine is important equipment in sheet metal processing, and its work accuracy directly affects the bending accuracy of the workpiece. In the bending process of the workpiece, the press brake machine is subjected to the greatest force at both ends of the slider, and the reaction force during the bending of the plate causes concave deformation on the lower surface of the slider. The deformation of the middle part of the slider is the largest, and the final bending angle of the workpiece The size varies across the entire length.

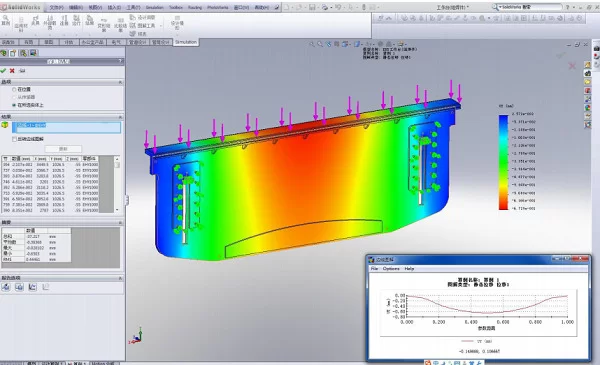

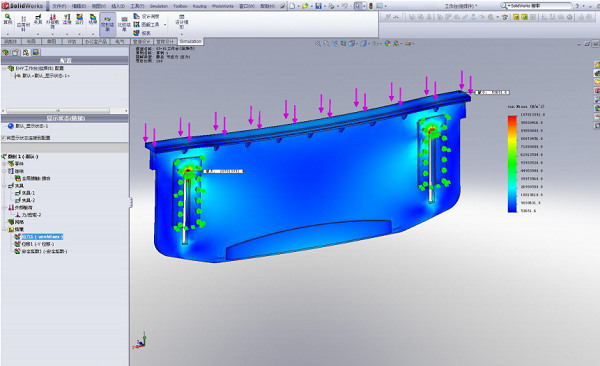

Workbench-full load-deformation

In order to eliminate the adverse effects caused by the deformation of the slider, it is necessary to compensate for the deflection deformation of the slider. The usual compensation methods include hydraulic compensation and mechanical compensation, both of which make the middle of the worktable produce upward elastic deformation to offset The deformation of the machine tool slide ensures the accuracy of the machining joint surface and improves the accuracy of the workpiece.

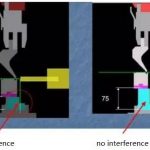

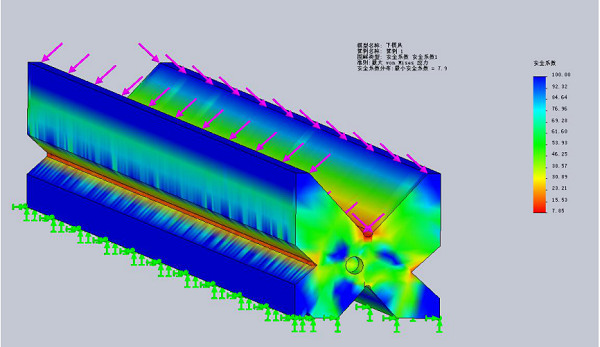

Mold safety factor analysis chart

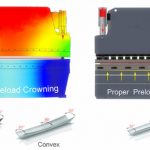

Two compensation methods

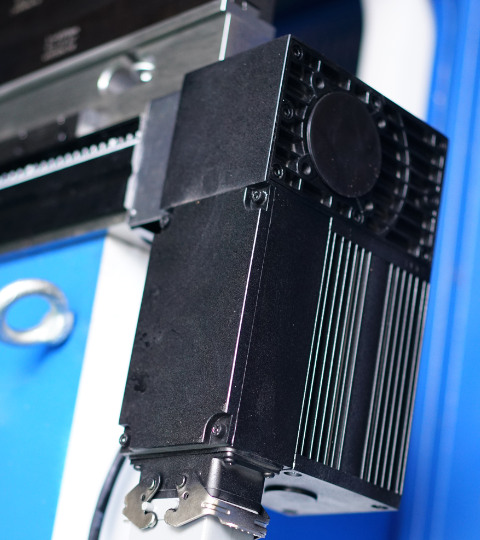

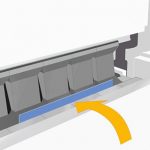

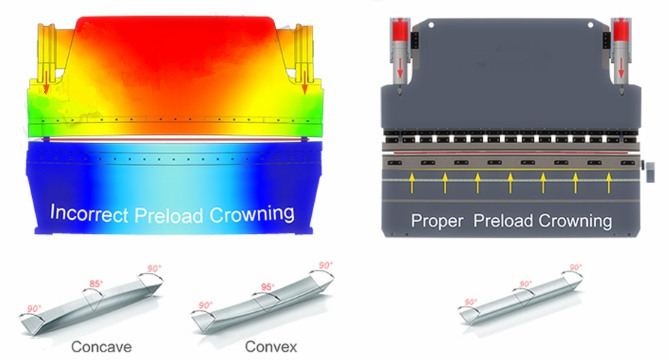

1. Hydraulic compensation

The hydraulic automatic deflection compensation mechanism of the workbench is composed of a group of oil cylinders installed in the lower workbench. The position and size of each compensation cylinder are designed according to the deflection compensation curve of the slider and the workbench finite element analysis. The hydraulic compensation is the bulge compensation of the neutral version that is realized through the relative displacement between the front, middle, and rear three vertical plates. The principle is to realize the bulge through the elastic deformation of the steel plate itself, so the compensation amount can be adjusted within the elastic range of the worktable.

2. Mechanical compensation

The mechanical compensation is composed of a set of protruding oblique wedges with inclined surfaces, and each protruding wedge is designed according to the deflection curve of the slider and the working table based on the finite element analysis. The numerical control system calculates the required compensation amount according to the load force when the workpiece is bent (this force will cause the deflection and deformation of the slider and the worktable vertical plate), and automatically controls the relative movement of the convex wedges to effectively compensate the deflection deformation produced by the sliding block and the vertical plate of the worktable can obtain the ideal bending workpiece. The mechanical deflection compensation is realized by controlling the position to achieve "pre-bumping". A set of wedges forms a line in the length direction of the worktable. The curve with the same deflection makes the gap between the upper and lower molds consistent during bending, ensuring the same angle of the bending workpiece in the length direction.